The technology of big data, cloud computing, IoT and mobile internet provide supports for the provincial Intelligent inspection control platform, to merge multi-sourse system data from space-sky-tower-earth. It has the functions of intelligent perception, active forewarning,?auxiliary diagnosis decision and?maintaining?and inspection intensive control and so on.

In view of the control platform specially customized by the provincial electric power maintenance company, it adapts?to the coverage of the whole province's business of transmission lines of 500kV and above, and builds an analysis and decision-making command system integrating information collection, process control, forwarning?research and judgment.

部分功能展示

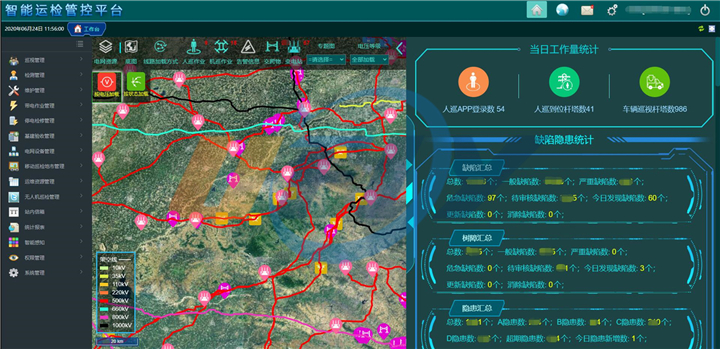

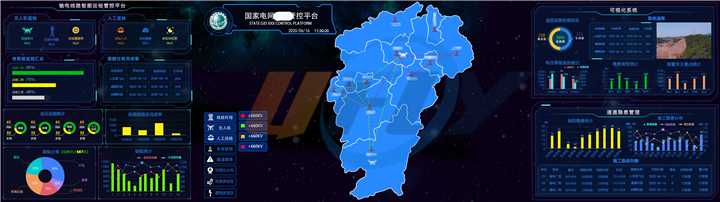

1.?Visual display on large screen

The system uses a large screen, integrates multi-source information fusion, data mining and information visualization technology, for improving capacity of management and control of intelligent perception and operations to maintenance equipment and environmental status information, building a professional intelligent system to realize the depth of the "Internet + grid inspection".

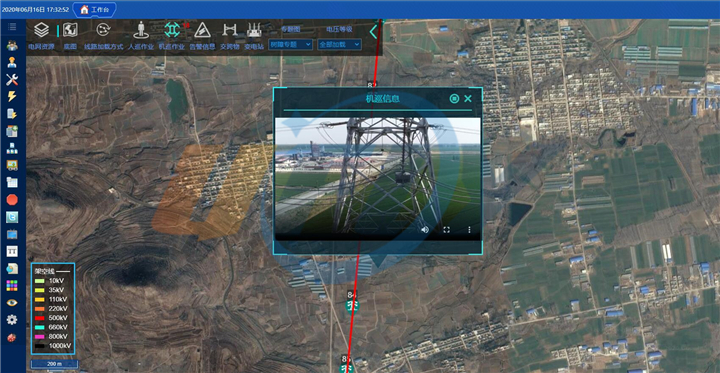

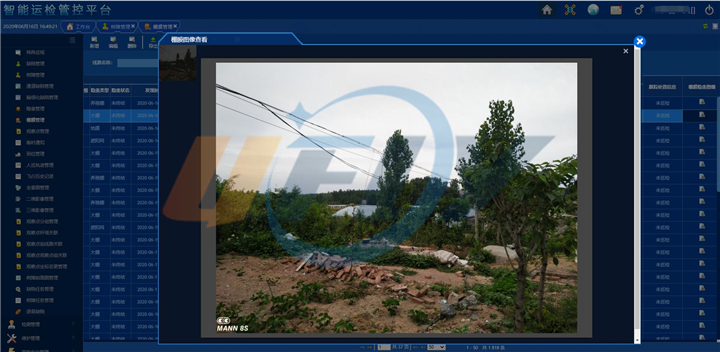

2.??Real-time monitoring of human patrol and aircraft patrol

Realize real-time monitoring of human patrol position and real-time image transmission of aircraft patrol.

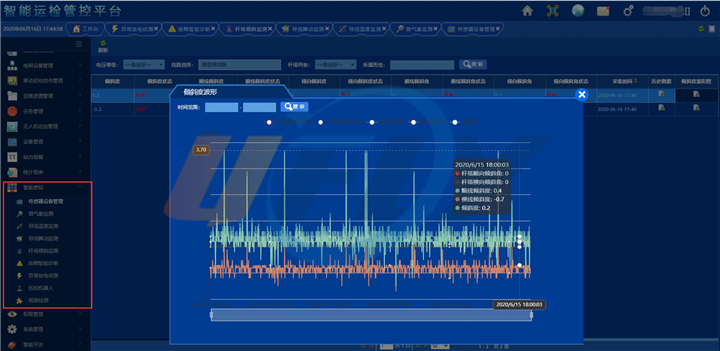

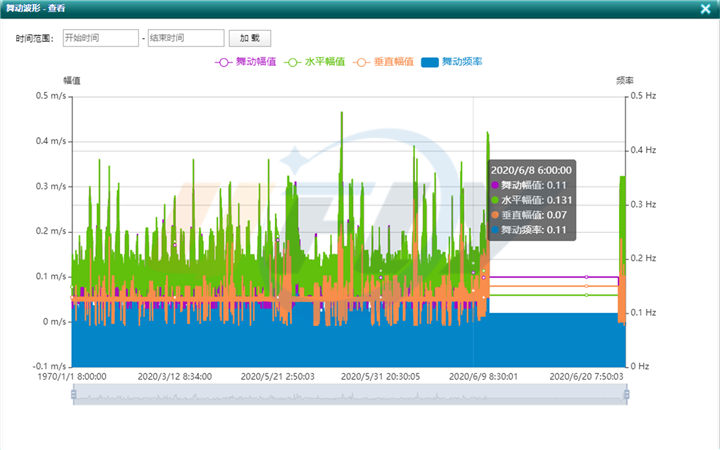

3.?IoT IntelliSense

Based on the IoT technology, and by installing various sensors, the platform?monitors?the running status and operating environment of transmission lines in real time, ?as well as realizing the panoramic holographic perception, interconnection and seamless integration of the whole process of power grid operation, making the perception and information processing of power Internet of Things more "intelligent".

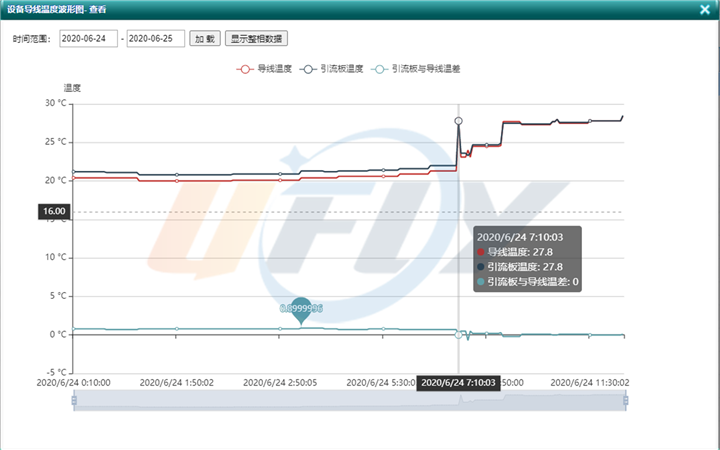

4. Online monitoring

Do the advantage of 3D?visualization, the platform closely integrates?with actual business scenarios such as operational maintenance,?with multiple?intelligent?technologies, such as intelligent monitor technology, image processing technology?and mobile Internet technology, to realize real-time monitoring?and forewarning to transmission operation maintenance, charged operation?and equipment running status, assisting inspection personnel?to capture?equipment running status?intuitively and rapidly.?

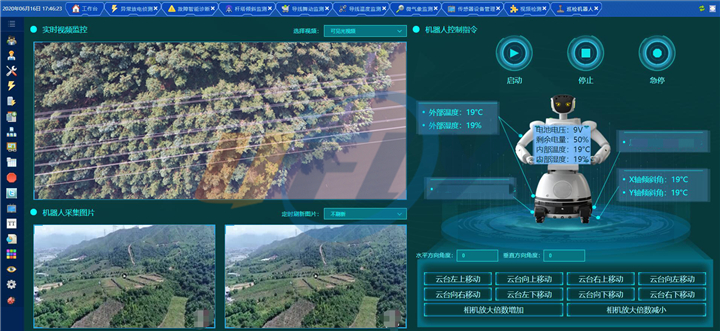

5. Join up with?robot

The robot is equipped with an autonomous and complete patrol system to achieve real-time video monitoring?and?control of the running condition?of the power grid, equipment and environment, and realize the full time, ?display and interaction?of the power grid operation data?in three-dimensional panoramic state.

6. Effectively manage planned tasks

It can realize the visual and closed-loop management of the whole process of inspection work, such as distribution of inspection work plan, assignment of tasks, on-site operation, completion of tasks and statistical analysis.

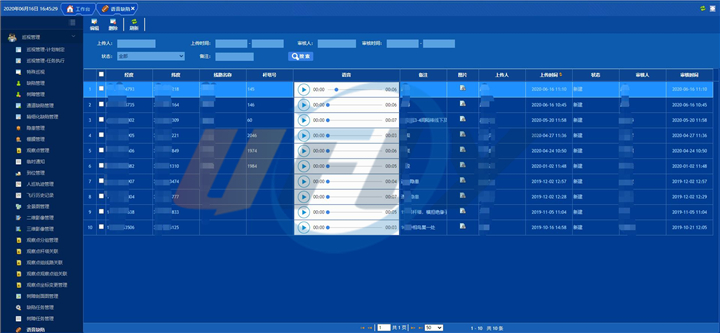

7. Intelligent Voice?Defect Management

The voice system facilitates aging patrol personnel?input defects?by voice, and makes the inspection process?simpler?and more intelligent.

8. Comprehensive coverage of three-dimensional inspection

It provides?comprehensive detection content, including but not limited to wire, ground wire, stay wire, insulator, grounding resistance, cross span, zero value, icing, metal, ancillary?facilities?and so on. Combining?with intelligent sensing sensors, it does the complete and safety detection for?line poles and towers.

9. Big data analysis and application

Based on the data onto?transmission equipment condition monitoring, detection, meteorology, operation and load, etc., through intelligent analysis,?it realizes?comprehensive diagnosis, differentiated evaluation, load capacity assessment and risk prediction of important transmission equipment, and form?into?a reference basis for transportation and inspection strategy and resource optimization.

? ? ? ?

Intelligent inspection control platform, responsible for?full accessing?and integration?of scheduling real-time information, production management, equipment condition monitoring, environmental monitoring, real-time video,?and inspection on site and so on. It provides comprehensive information supports for integrated operation of the grid monitoring, production scheduling and emergency accident disposal, and realizes?creatively development and improve efficiency?to data driven?inspection, as well as?improve the penetration of inspection management and equipment state control?power.